Many workplaces include some form of flammable gas/vapour or combustible dust type hazard and associated risk. From smaller areas like a paint spray booth facility to large industrial settings such as a chemical manufacturing plant, hazards are inherently part of operating in a particular environment. Understanding those hazards, and managing their risk is crucial.

Advitech’s Process Engineering and Sustainability group has a wealth of experience in hazardous area assessment, dangerous goods, hazardous chemicals and managing safety compliance. Advitech’s lead consultant in this area, Dr Carl Fung, leads a team of experienced process engineers that specialises in the discipline of Process Safety.

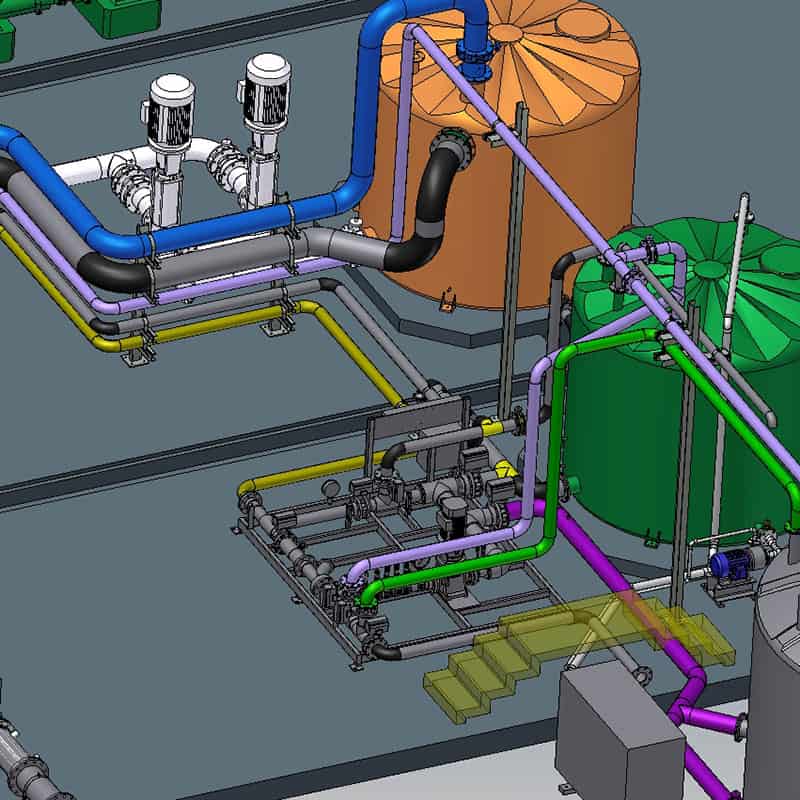

Process safety is a framework for managing the integrity of operating systems and processes that handle hazardous substances. It relies on good design principles, engineering and operating and maintenance practices.

“If you’re working in a hazardous environment or with dangerous substances, you owe it to your people and the ecosystem in which your workplace exists to understand the hazards and have a plan to manage the risks associated with them,” said Dr Fung.

Advitech has worked with organisations from a diverse range of industries to assess their workplace hazards, categorise those hazards and manage them in accordance with Workplace Health and Safety (WHS) standards, Australian Standards and legislation. Dr Fung believes that organisations want to be compliant with relevant standards and legislation but that they require help to get there.

“Regulation and legislation can be complicated and tricky to navigate without specialised knowledge. That’s where we can help, because we understand the factors that contribute to a hazardous environment and we have tried and tested methodologies for analysing such situations and customising approaches for achieving compliance.”

Sydney Water, one of Australia’s largest water utilities, wanted to gain a greater understanding of process safety across their plants and to identify safety concerns and opportunities for improvement. Advitech was chosen to audit 20 wastewater, water and major hazard facilities plus facilitate risk assessments on the potential failure modes of operation. Through a collaborative and efficient safety audit process and benchmarking against industry best practices, Advitech’s process engineers contributed to enhanced safety and improved maintenance efficiencies for the client.

More recently, Advitech worked with one of Australia’s leading glass bottle manufacturers. Having introduced a change to their manufacturing process, they felt it timely to conduct a hazardous area assessment and classification of their batch house, the storage facility for raw materials. Among many observations, Advitech identified the potential for particular materials to form explosive dust atmospheres. Our report to the client outlined options for addressing and mitigating this through better engineering design, management and staff training.

A major food manufacturer invited Advitech to tender for a review of their plant and processes at their Victorian facility. Advitech won the tender and undertook a hazardous area audit, assessment and equipment inspection. The comprehensive review found a number of areas where safety, particularly around hazardous materials, could be improved. The final report to the client outlined the conclusions and recommendations, including practical timelines and estimates of cost.

Across a broad range of industry sectors and facilities large and small, Advitech can help identify your process safety issues and make recommendations for achieving compliance.

Contact Advitech’s Process and sustainability team on (02) 4924 5400.