Background

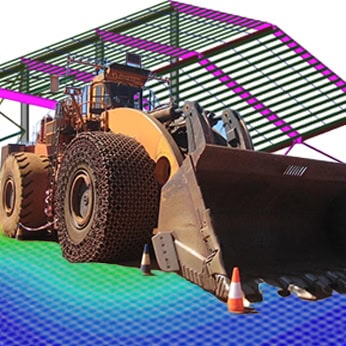

It likely comes as no surprise that mine sites regularly use and operate heavy machinery. Some of these vehicles like the CAT 793 and Le Tourneau L1850 front loader can weigh in at around 300 tonnes. To safely and efficiently service and repair these vehicles, a Hunter Valley mining business was considering the establishment of a sheltered tyre changing facility. The facility needed to accommodate heavy machinery, ensure safe and efficient operational spaces, and withstand the mine’s challenging environmental conditions.

Advitech was brought on board as part of an initial feasibility study, to develop the concept structural design for the facility. During the initial site inspection with the client’s project manager, we delved into their objectives and goals. Our evaluation covered terrain conditions, site constraints, large truck accessibility, utility availability, and the site’s proximity to key mine operations.

Solution

After reviewing the site and project goals, our structural engineering team designed a solution that would meet the needs of the client and uphold industry standards.

Key highlights:

A reinforced concrete slab – including the extension of the existing tyre changing area and the addition of heavy-duty floor slabs. The slab was designed to accommodate the dynamic loads from mining vehicles.

A portal frame structure – Portal frames offer a robust and flexible shelter solution. Our design featured a clear height of 13.5 m over a 27 x 30 m area. Uncladded side walls for access from all sides and steel framing roof purlins offered corrosion protection and enhanced roof load capacity from the elements.

A stormwater system – Designed to manage rainwater runoff effectively and prevent operational disruptions or environmental hazards. Consideration for potential drain blockages, with alternative overflow pits and surface discharge options were integrated into the design.

Once the design was complete, our team gathered construction quotes from established regional construction companies to evaluate the financial feasibility of the facility upgrade. We prepared a tender summary, including scope of work, concept design, drawings and relevant specifications. An evaluation of quotes was provided to the client, based on pricing, timelines and contractor reputation.

Conclusion

The structural design of the tyre changing facility by Advitech illustrates a comprehensive approach to meeting the client’s needs while adhering to industry standards. The combination of reinforced concrete design, a strong portal frame roof structure, and an effective stormwater management system ensures that the facility will operate efficiently and safely in the demanding environment of a mine site.

If you’re looking for expert solutions tailored to your specific needs, we invite you to get in touch with Advitech today. Let’s discuss how we can help you achieve your project goals with precision and reliability!