Getting Ahead of Compliance Before It’s Critical

Australia’s industrial safety landscape is maturing and for machinery operators, and plant supervisors the pressure to meet their regulatory requirements is mounting. With growing awareness around machinery-related hazards, businesses are being urged to act early, not react late.

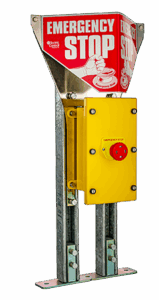

That’s exactly what a regional water management facility did during a major pump upgrade project. Before installation began, the team identified a critical need: a compliant, reliable emergency stop system that would meet both technical performance standards and legal obligations.

Rather than waiting until after installation to verify compliance, they engaged Advitech to independently assess the system’s design, ensuring it was safe, effective, and ready for real-world operation.

The Challenge

Under WHS regulations, machinery owners and operators must take reasonably practicable steps to protect workers from hazards. That includes specific requirements around the configuration and performance of emergency stop systems.

The project team referred to AS4024.1503: Safety of Machinery – Safety-Related Parts of Control Systems, a standard that outlines how safety circuits should be designed, implemented, and validated. With multiple stakeholders involved and a significant investment at stake, they needed more than a checklist, they needed assurance.

Advitech’s Role: Independent Verification with Impact

Advitech provided independent verification of the emergency stop system. The team reviewed design documentation, assessed system architecture, and benchmarked the solution against both AS4024.1503 and NSW WHS regulations.

But the work didn’t stop at compliance. Within just three weeks, Advitech collaborated with the client to refine the system; improving reliability, simplifying implementation, and ensuring the design was both effective and efficient.

The Outcome: Safety assured

- Verified compliance with AS4024.1503 and NSW WHS regulations

- Identified design improvements

- Delivered expert review and recommendations within 3 weeks

- Enabled confident decision-making and stakeholder alignment

- Supported a safer workplace for frontline workers

Why It Matters

In high-risk operational environments, the risks to people from machinery are real and emergency stop systems are the last line of defence. But they only work if they’re designed, installed, and verified correctly.

With NSW’s WHS regulations removing ambiguity and increasing accountability, expert verification is an essential step for the peace of mind for any machine operator. This case shows how early action, expert advice, and independent verification can turn uncertainty into confidence and ensure that compliance isn’t just met but that operational requirements are exceeded.

Need help verifying your emergency stop systems?

Contact our team to learn how Advitech can support your compliance journey and help safeguard your workplace.